-

Since 1996Professional Cardboard Grooving

Since 1996Professional Cardboard Grooving

Machine Manufacturer - Home

- About

- Product

- Service

- Innovations

- Case

- News

- Contact us

-

- EN

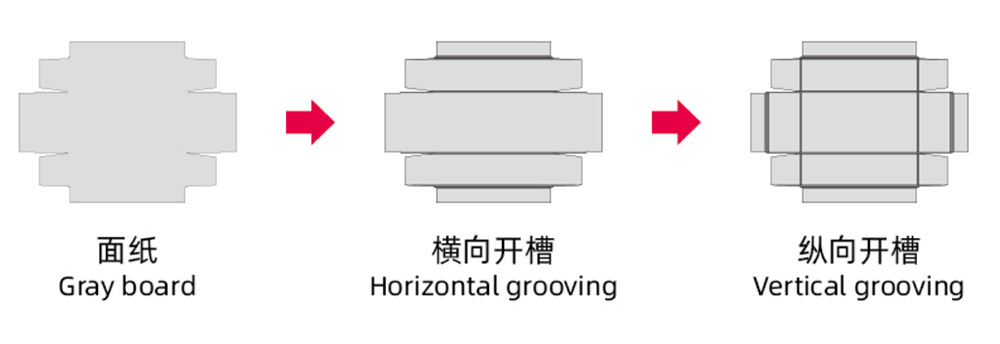

For cutting v shape groove on the different material ,such as coated paper ,thin paperboard ,art paper ,Ivory board , it can make the rigid boxes with the best straight edges and 90 degree corners ,so as to increase the visual effect of the boxes and improve the quality grade of boxes. The boxes can be rigid box ,luxury box ,jewelry box ,electronic product box ,cosmetic box ,etc .

|

Function |

Technical parameter |

|

Material size of 1st step |

Length 195-560mm ,width 195-560mm |

|

Material size of 2nd step |

Length 195-560mm, width 195-560mm |

|

Grooving knives of 1st step |

6 sets |

|

Grooving knives of 2nd step |

6 sets |

|

Best accuracy |

±0.05mm |

|

Normally accuracy |

±0.1mm |

|

Material thickness |

200-350GSM |

|

Grooving angle |

80-140 degree adjustable , (90º=80º-110º ,120º=110º-140º) |

|

Angle adjustable type |

Each knife head can be adjustable independently |

|

Speed |

80-100PCS/Min |

|

Quantity of girder (crossbeam ) |

2 sets |

|

Quantity of knife row |

3 rows ( 1 rows of knives on the 1st girder ,2 rows of knives on the 2nd girder ) |

|

The way of feeding paper |

Feida air feeding system |

|

Platform type of adding paper |

Upper and lower platform ( save the time of paper putting ) |

|

Adjustable knife left position or right |

Servo automatic positioning |

|

Grooving depth |

Manual adjustment is required for the first time . When you change the product and the knife, as long as the grooving angle is unchanged, there is no need to adjust the depth by second time . |

|

Rolling belt adjustment |

Remove the belt quickly by handwheel |

|

Waste cleaning system |

Automatic waste cleaning system with air system+ 2 dedicated conveyor belts |

|

Weight |

5200KGS |

|

Power |

13.5KW |

|

Machine dimension |

3200*2950*1570mm |

|

Edge correction principle of 1st step |

Belt correction + steel ball correction |

|

Edge correction principle of 2st step |

Belt correction + steel ball correction |

|

90º turn around system ( direction change ) |

Drum flipping |

|

Video link |

https://youtu.be/dGh7Fkwu9-Q |

If you have any enquiry about quotation or cooperation,please feel free to email us at sunny@chinajsy.com or use the following enquiry form. Our sales will contact you within 24 hours. Thank you for your interest in our products.

GET A QUOTE