-

Since 1996Professional Cardboard Grooving

Since 1996Professional Cardboard Grooving

Machine Manufacturer - Home

- About

- Product

- Service

- Innovations

- Case

- News

- Contact us

-

- EN

Recently, saili customers have struggling with how to make the firmness and aesthetics of their " double wall folding boxes" , see how SAILI customised a new grooving solution for our customer.

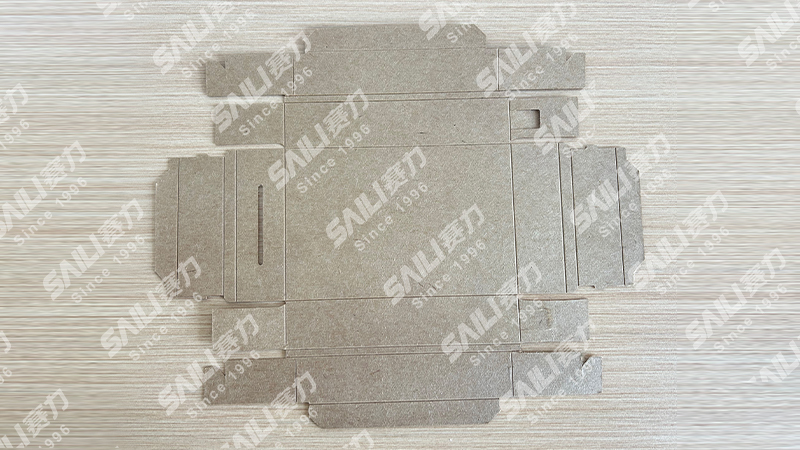

1. 8 grooves are needed in each direction, with very small spacing between grooves.

2. The need for a combination of regular V-grooves and partial V-grooves.

The so-called cardboard partial V-groove is V groove is not in the same horizontal line, but choose the middle or both ends of the cardboard for a certain distance V groove operation.

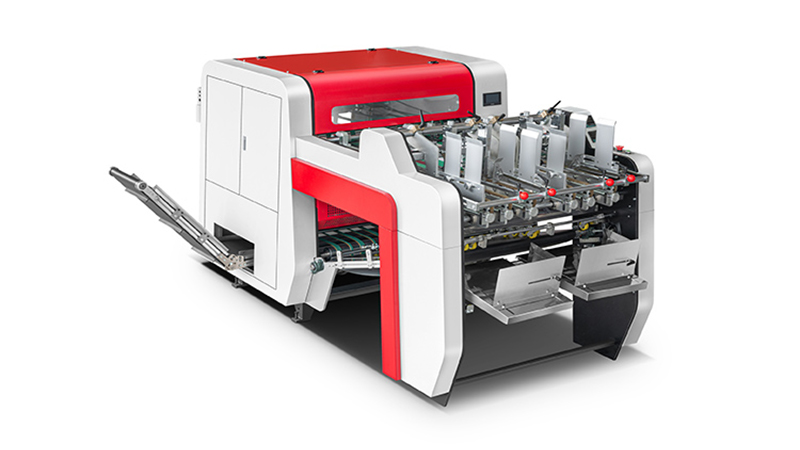

Saili grooving machine has two rows of beams and four rows of knives to help solve the problem of groove spacing.

Saili grooving machine is equipped with two types of grooving knives: regular V-groove and partial V-groove. So easily solves customers' grooving problems.

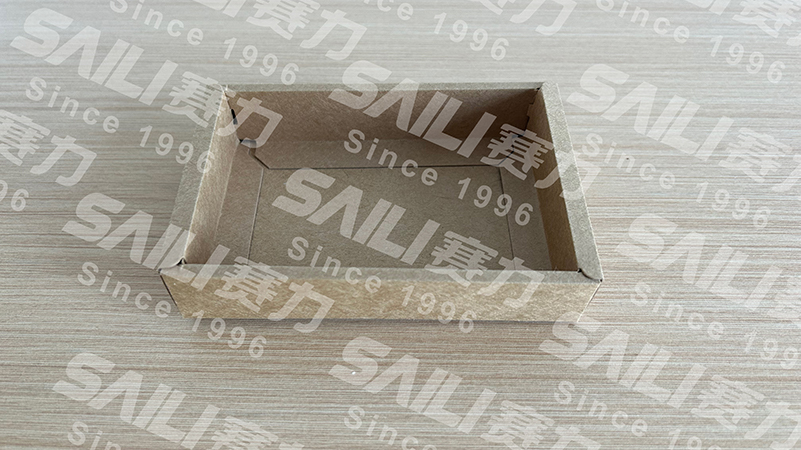

This world's first grooving technology, realised through partial V-groove, creates cardboard into the ultimate tactile double wall folding box. The unique structure and design of the precisely grooved and folded Double Wall Folding Box achieves a three-dimensional reinforced effect after forming. Its innovative partial V-groove simplifies the assembly process and significantly improves the overall support performance, and the angular three-dimensional shape of the box significantly improves the box's pressure resistance.

The SLZ-928C automatic partial grooving machine is suitable for both regular v groove and partial v groove, compatible with various board including grayboard and thin cardboard. The machine adopts a servo system to control the in-and-out movement of grooving blades, enabling partial V-groove. With a minimum grooving depth precision of 0.01 mm, it achieves exceptionally accurate grooving.

Featuring fully automated operation, the machine comes equipped with automatic feeding and discharging functions, with waste materials automatically expelled from the system. This eliminates the need for manual waste removal, significantly enhancing production efficiency while reducing labor costs.

GET A QUOTE