-

Since 1996Professional Cardboard Grooving

Since 1996Professional Cardboard Grooving

Machine Manufacturer - Home

- About

- Product

- Service

- Innovations

- Case

- News

- Contact us

-

- EN

In the modern packaging industry, with its unique structure and beautiful appearance, the box is widely used in gifts, cosmetics, electronic products and many other fields. In the production process of the box, there is a key link that is indispensable, that is, corner cutting and slotting. Today, we will have an in-depth understanding of the corner cutting and grooving machine specially used for this process.

The corner cutting and grooving machine uses advanced mechanical technology and precise control system to achieve accurate processing of grey board and cardboard. Its working principle is mainly through the rotation and movement of the cutter, according to the preset parameters and paths, to cut and groove the material operation.

During corner cutting, the machine's knives cut into the material at a specific angle and speed to ensure that the corners are cut neatly and accurately. Grooving, on the other hand, is done through precise positioning and control to create the required slots in the sheet to facilitate the assembly of the canopy box. This series of operations seems simple, but behind the complex mechanics, motion control and precision adjustment principles, need the machine components work together to achieve high-quality processing results.

1. High-precision machining

The machine is capable of achieving extremely high dimensional accuracy, ensuring that the dimensions of the cut corners and grooves are highly consistent with the design requirements. Whether it is a small error or precise angle control, all can be accurately grasped. For a box with an open-end lid, this means that the various parts of the box will fit perfectly, and the assembled box will have a solid structure and a flat and beautiful appearance. For example, in the production of high-grade gift boxes, precise dimensional accuracy can make the lid and the bottom of the box fit tightly, enhancing the overall texture of the product.

2. Shape accuracy

In addition to dimensional accuracy, the machine also excels in ensuring shape accuracy. It is able to cut various shapes of corners and slots, such as right angles, rounded corners, bevelled edges, etc., according to different design requirements, with regular shapes and smooth lines. This precise control of the shape provides more possibilities for the design innovation of the box with sky and earth cover, so that the packaging can better adapt to the characteristics of different products and market demand.

3. Efficient production capacity

In modern industrial production, efficiency is a crucial factor. Tiandi lid box corner cutting and slotting machine has high efficient processing speed, and can complete a large number of corner cutting and slotting tasks in a short period of time. Compared with traditional manual operation or inefficient equipment, it greatly shortens the production cycle and improves production efficiency. This enables companies to meet customer orders in a shorter period of time and enhance market competitiveness.

4. High degree of automation

The machine is usually equipped with an advanced automation control system, which is capable of automatic feeding, automatic positioning, automatic cutting and slotting as well as automatic unloading. The operator only needs to make simple settings and monitoring, the machine can automatically complete a series of processing processes, reducing manual intervention, not only improving production efficiency, but also reducing labor intensity and the incidence of human error.

5. Wide material adaptability

There are various materials for the production of Tiandi cover box, including grey board and cardboard of different thickness and materials. This corner cutting and slotting machine has excellent material adaptability and can easily cope with the processing needs of various materials.

For different thicknesses of boards, the machine can adjust the height of the tool and processing parameters to ensure that the depth of the cutting and grooving is moderate, neither too deep to damage the internal structure of the material, nor too shallow to affect the processing effect. At the same time, for the characteristics of different materials, such as the hardness of grey board and the flexibility of cardboard, the machine is able to optimise the processing process to ensure that high-quality corner cutting and grooving effects can be achieved on a variety of materials. This makes the enterprise more flexible in the choice of materials, according to the positioning of the product and cost requirements, choose the most appropriate material for production.

1. Gift Packaging Industry

In the field of gift packaging, heaven and earth cover box is a common form of packaging. Exquisite gifts need matching high-quality packaging to enhance the sense of value. The box corner cutting and slotting machine provides gift packaging companies with a powerful tool to achieve this goal.

With neat corners and precise slots, the boxes processed by this machine are able to perfectly showcase the charm of the gift. Whether it is a high-end jewellery box, a delicate watch box or a creative gift box set, all of them can produce professional quality packaging with the help of this machine. It not only enhances the appearance of the image of the gift, but also provides better protection for the gift, increases the added value of the gift, and meets the needs of consumers for high-quality, personalised gift packaging.

2. Cosmetic packaging industry

Cosmetic industry for packaging requirements are extremely high, not only to focus on the appearance of aesthetics, but also consider the practicality of packaging and protection. Tiandi cover box corner cutting and slotting machine plays an important role in the production of cosmetic packaging.

For cosmetic boxes, precise corner cutting and slotting can ensure the close combination of the lid and the bottom of the box, preventing the cosmetics from leaking or being damaged during transport and storage. At the same time, the machine is able to customise various specifications of sky and earth lid boxes according to different shapes and sizes of cosmetics to meet the packaging needs of different products. Moreover, through the fine processing technology, it can produce cosmetic boxes with exquisite appearance and superior texture, which can enhance the brand image and attract consumers' attention.

3. Electronic product packaging industry

The packaging of electronic products needs to have good cushioning performance and structural stability to protect the products from collision and extrusion. Tiandi lid box corner cutting and slotting machine can provide reliable solutions for electronic product packaging.

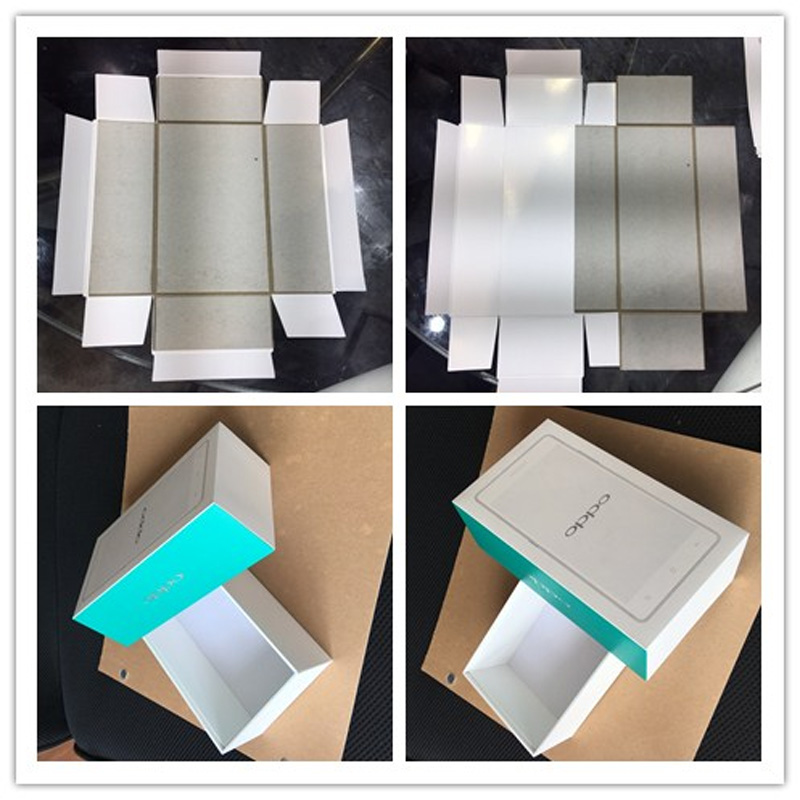

Through rational design and processing, the boxes made by this machine can provide solid support and protection for electronic products. Precise corner cutting and slotting makes the assembly of the box tighter and enhances the strength of the overall structure. At the same time, the machine can be customised according to the size and shape of the electronic product, ensuring that the box matches the product perfectly and improving the efficiency and quality of the packaging. In today's highly competitive market for electronic products, high-quality packaging not only protects the product, but also enhances the product's market competitiveness and wins more market share for the enterprise.

SLG - 600BG Automatic Corner Cutting And Bidirectional Grooving Machine is a newly invented machine based on rich experience in automatic bidirectional grooving machinery manufacturing. It is capable of cutting both horizontal and vertical V-grooves (U-grooves) in a single feeding, and is suitable for a wide range of hard shell covers as well as boxes with open and closed lids, including mobile phone boxes, shoe boxes, cosmetic boxes, and cardboard boxes, among others.

The machine consists of four main sections: automatic corner cutting, first slotting section, second slotting section and a special conveyor belt for transporting the final cardboard. It uses longer alignment devices as well as collection and conveying parts to ensure that the cardboard enters each slotting section straightly, thus improving slotting accuracy and avoiding the problem of uneven corners of boxes caused by poor slotting accuracy. With its many advantages, it not only improves product quality, but also increases production efficiency and saves labour.

As an important equipment in the packaging industry, Tiandi lid box corner cutting and slotting machine provides solid technical support for the production of Tiandi lid box with its high precision, high efficiency and wide adaptability. It plays an important role in the application of different industries and promotes the development and progress of the packaging industry. With the continuous innovation and development of technology, we believe this machine will show more excellent performance and unlimited possibilities in the future, creating more value for the development of various industries. Let us look forward to its wonderful performance in the future packaging field, bringing us more beautiful packaging products and more convenient production experience.