-

Since 1996Professional Cardboard Grooving

Since 1996Professional Cardboard Grooving

Machine Manufacturer - Home

- About

- Product

- Service

- Innovations

- Case

- News

- Contact us

-

- EN

In the modern cardboard processing industry, the introduction of an Auto Feeder has significantly enhanced the efficiency of Cardboard Score Slitting Machines. This article explores how an Auto Feeder optimizes production processes, boosts efficiency, and helps cardboard processing businesses achieve higher output with lower operational costs.

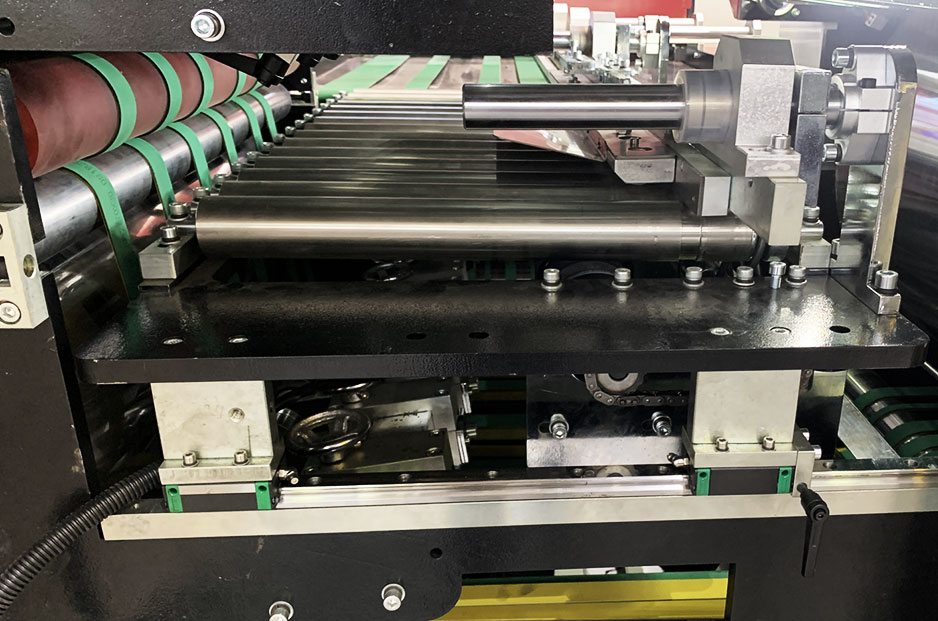

Traditional cardboard processing requires manual loading of raw cardboard into the machine, which is not only inefficient but also prone to operational errors that can disrupt production. An Auto Feeder, with its intelligent conveying system, automates the feeding process. Simply place the raw cardboard in the designated area, and the machine will automatically feed it into the Cardboard Score Slitting Machine for processing. This fully automated design not only reduces labor costs but also significantly improves production efficiency, making it ideal for large-scale production needs.

The Auto Feeder uses high-precision sensors and control systems to ensure that each piece of cardboard is accurately fed into the Cardboard Score Slitting Machine. This precision eliminates the deviations often caused by manual operations, ensuring straight and smooth cutting edges while minimizing material waste.

After the initial cutting process, the Auto Feeder seamlessly integrates with collection and stacking systems. Semi-finished cardboard is automatically collected and conveyed to a stacking table, ready for secondary cutting. This integrated design reduces manual intervention and ensures orderly processing, further enhancing overall production efficiency.

By incorporating an Auto Feeder, businesses can significantly reduce their reliance on manual labor, thereby lowering labor costs. Additionally, the automated process minimizes human errors, material waste, and equipment downtime. In the long run, this efficient production method can substantially improve return on investment (ROI), delivering greater economic benefits to businesses.

Whether for small-batch custom orders or large-scale production, the Auto Feeder can handle it all. By working in tandem with the Cardboard Score Slitting Machine, businesses can quickly switch between different cardboard specifications, meeting diverse customer demands. This flexibility gives businesses a competitive edge in the market.

The high-precision feeding and cutting capabilities of the Auto Feeder reduce material waste, while its automatic edge waste cleaning feature ensures a clean production environment. This eco-friendly design aligns with the sustainability goals of modern manufacturing and helps businesses reduce waste disposal costs.

The combination of an Auto Feeder and a Cardboard Score Slitting Machine has revolutionized efficiency in the cardboard processing industry. Through fully automated processes, precision feeding, efficient collection, and eco-friendly design, businesses can achieve higher production efficiency, lower operational costs, and stronger market competitiveness.

If you’re looking for a solution to significantly enhance your cardboard processing efficiency, an Auto Feeder is the ideal choice. Contact us today to learn more about how automation can optimize your production processes!

GET A QUOTE