-

Since 1996Professional Cardboard Grooving

Since 1996Professional Cardboard Grooving

Machine Manufacturer - Home

- About

- Product

- Service

- Innovations

- Case

- News

- Contact us

-

- EN

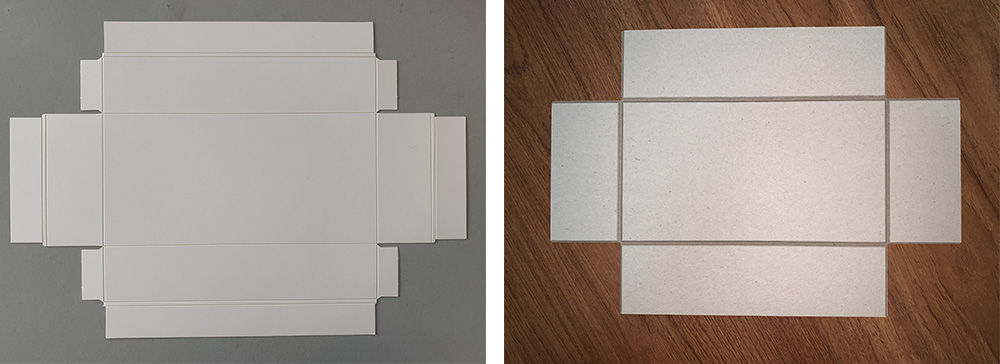

When folding milk cartons, fold the bottom, sides and top along the die cut lines to ensure that each folded side is aligned and securely closed. The die cut lines provide accurate folding guidance and ensure that the box is structurally sound.

As a common form of packaging in our daily life, milk cartons are not only convenient for storage, but also effective in protecting the contents. Folding milk cartons is a crucial step in the production process that requires precision and efficiency. And in order to enhance the efficiency of this process, automated equipment, such as automatic grooving machines, are beginning to be widely used in the packaging industry. Today, we will share with you how to fold milk cartons according to the die-cutting line, and introduce how automatic grooving machines can help the packaging industry achieve automation and efficiency.

The die-cutting line is a key part of the box design, which enables the box to be shaped quickly and accurately during production through precise cutting and folding line design. Milk cartons are usually produced with a series of die-cutting lines, which mark the exact position of folding and cutting to ensure that the final box has a standard form and solid structure.

Before you start folding milk cartons, you need to ensure the following steps:

* Check the die-cutting lines: Firstly, double check that the die-cutting lines are clear and undamaged. If the die cut lines are blurred or damaged, a stable structure may not be formed after folding. Gently touch the die cut line to ensure that the fold line is accurate and not broken.

* Clean the packing material: Before folding, make sure that the wrapping cardboard is free from dirt or debris, which can avoid affecting the folding effect and the aesthetics of the package.

Fold along the die-cutting line: According to the guidelines of the die-cutting line, gently fold along the line. The die-cutting line provides the direction and position of folding, so there is no need to use excessive force when folding, gently fold along the line.

* Starting from the bottom: It is generally recommended to start folding from the bottom of the milk carton. Start by folding the bottom fold line inwards and make sure the bottom is securely closed.

* Fold the sides: Next, fold the sides of the box along the die cut lines. Make sure the sides are folded neatly and aligned.

* Seal the top: Finally, seal the top following the die cut lines. Make sure the top is sealed tightly to prevent liquid leakage.

* Handle gently: When folding, use a gentle gesture and avoid applying excessive force. Excessive pressure may cause damage to the paper and affect the overall structure.

* Dry environment: A wet environment may affect the structure of the paperboard and lead to unstable folding. It is recommended to operate in a dry environment to ensure the best folding results.

With the market's increasing demand for production efficiency and packaging quality, automatic grooving machine, as an efficient production equipment, began to play an important role in the packaging industry. Automatic grooving machine can not only accurately hit the die-cutting line on the cardboard, but also can automatically complete the grooving and folding operations, greatly improving production efficiency.

With precise control through automated procedures, the automatic slotter can complete a large number of box die-cutting and grooving jobs in a short period of time. This not only dramatically improves production efficiency and reduces the error rate of human operation, but also ensures that the folding and grooving lines of each box are precise and accurate, thus guaranteeing the quality of packaging.

For the production of milk cartons, the automaticgrooving machine can quickly and accurately hit the die-cutting line, which helps the producer to significantly increase the production speed and reduce manual folding errors. The introduction of automated equipment makes the packaging production line more efficient and accurate, and reduces the labour costs in the production process.

Folding milk cartons according to the die-cutting line is a basic process in packaging production, and the introduction of automated grooving machines has brought a huge boost to this process. Through accurate die-cutting and automated grooving, the automatic grooving machine not only improves the packaging efficiency, but also ensures the quality of packaging, which brings considerable economic benefits to the producers.

Understanding the role of the die-cutting line and mastering the correct folding techniques are key to ensuring flawless milk carton packaging, both in traditional manual operations and in modern automated production. With the application of automatic grooving machines and other equipment, the packaging industry will usher in a new era of more efficient and accurate production.

GET A QUOTE