-

Since 1996Professional Cardboard Grooving

Since 1996Professional Cardboard Grooving

Machine Manufacturer - Home

- About

- Product

- Service

- Innovations

- Case

- News

- Contact us

-

- EN

In the fast-paced world of industrial packaging, efficiency and precision are critical. Cardboard, the primary material used to make cartons, displays, and protective packaging, must be cut to precise specifications. That’s where slitter machine come in handy. Cardboard slitter machine ensure high-precision cutting, optimize material utilization, and reduce waste.

This article explores the role of slitter machine in packaging, their benefits, and how high-precision slitting can enhance production processes.

A slitter (or slitter) is an industrial cutting device used to cut large rolls or sheets of material such as cardboard, paper, plastic, or metal into narrower strips with extreme precision. In the packaging industry, cardboard slitter machine are essential equipment for converting large-size cardboard into custom widths for making cartons, displays, and other packaging solutions.

1. Unwinding - Feeding large rolls or sheets of cardboard into the machine.

2. Slitting - Sharp rotary blades or lasers cut the material to precise widths.

3. Rewinding or stacking - Slit cardboard strips can be rewound into smaller rolls or stacked for subsequent processing.

Modern high-precision slitting systems are computer-controlled to ensure cutting consistency, minimize material waste, and maximize efficiency.

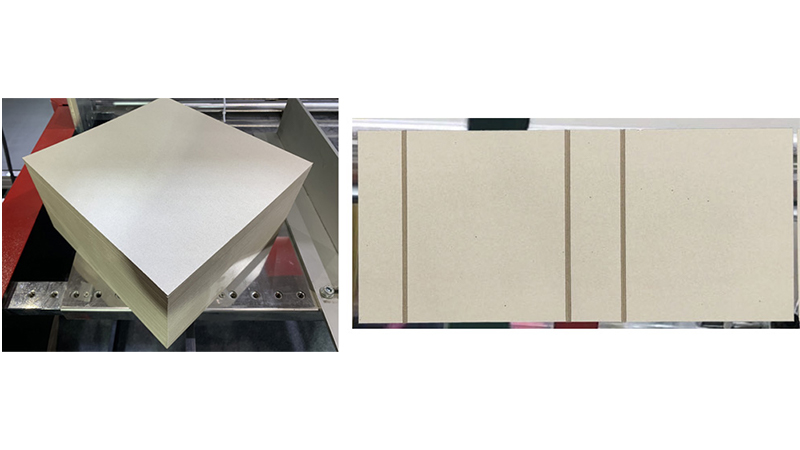

Traditional cutting methods often result in uneven edges or excessive waste. Saili high-precision slitting (±0.15) cuts cleanly and evenly, reducing waste and improving cost-effectiveness.

Saili has a variety of automatic and fully automatic high-precision slitting machines. Its automated slitting machines process materials much faster than manual methods, making them ideal for high-volume packaging operations where speed is critical.

A wide range of materials can be processed, including corrugated board, paperboard, and foam.

Adjustable blade settings allow for different slitting widths to meet different packaging needs.

In areas where labor wages are high, automation minimizes the need for manual cutting, reducing labor costs. Operators only need to debug and monitor the machine to work efficiently, greatly improving workplace safety.

Saili clean, burr-free edges improve the appearance and functionality of the final product, which is essential for industries that require high-end products and precise dimensions (high-end packaging, e-commerce packaging).

Slitting technology is widely used in various industries, including:

1.E-commerce and logistics – producing custom-sized cartons for different products.

2.Food and beverage packaging – creating precise packaging for cereal boxes, beverage cartons, etc.

3.Retail display – cutting cardboard for point-of-sale (POS) displays and shelf-ready packaging.

4.Industrial Packaging – Create protective liners and dividers for fragile items.

When choosing a cardboard slitter, consider the following factors:

1.Material compatibility – Make sure the machine can handle the thickness and type of cardboard used.

2.Cutting accuracy – Look for high-precision slitting capabilities and minimize tolerances.

3.Automation level – Choose a semi-automatic or fully automatic model based on production needs.

Slitter is the cornerstone of modern packaging production, and Saili can provide high-precision slitter, efficient and cost-saving. As the demand for customized and sustainable packaging continues to grow, investing in advanced cardboard slitter will be key for manufacturers to remain competitive.

GET A QUOTE