-

Since 1996Professional Cardboard Grooving

Since 1996Professional Cardboard Grooving

Machine Manufacturer - Home

- About

- Product

- Service

- Innovations

- Case

- News

- Contact us

-

- EN

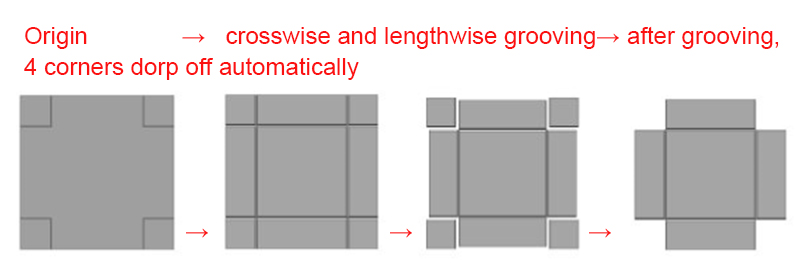

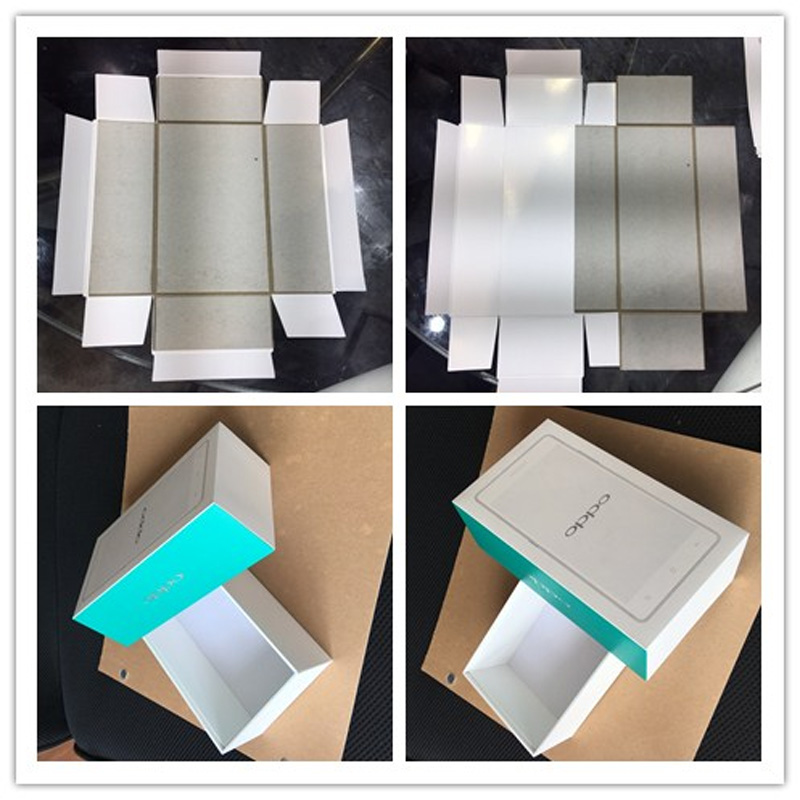

This machine is newly invented based on the rich experience of automatic bidirectional grooving machinery manufacturing. It can able to cut out the crosswise and lengthwise v- groove (u-groove) on the board by once feeding. It’s suitable for various of hard cover and Lid & base boxes ,include Mobile phone boxes,shoe boxes,cosmetic boxes,rigid boxes,etc .

Advantages :

The machine is mainly include 4 parts : automatic corner cutting , first grooving part ,second grooving part ,dedicated conveyor belt for delivery final cardboard .

Use longer aligning device and collecting & conveying part to ensure that the cardboard go straight into each grooving parts,then improve the grooving accuracy ,to avoid the high and low corners of box by poor grooving accuracy .

Improve product quality, improve production efficiency, saves labor .

Technical parameter :

|

Material Width |

150-600mm |

|

Material Length |

200-600mm |

|

Material thickness |

1.2-3.0mm |

|

The grooving accuracy |

±0.1mm |

|

Grooving angle |

80-140degree adjustable |

|

Grooving tool on the first step |

8sets |

|

Grooving tool on the second step |

4sets |

|

Corner cutting accuracy |

≤0.2mm |

|

Way of corner cutting |

Servo knife cutting ,cutting length is Control by PLC |

|

Machine power |

7.5KW |

|

Speed |

80-120PCS/Min (200*200mm) |

|

Main dimension |

3700*3100*1525mm |

|

Weight |

2850KGS |

|

Groove shape |

V shape (L shape , U shape customized) |

|

Function : 1 Auto feeding → 4 corner die cutting→ crosswise grooving →conveying →lengthwise grooving→Auto collector |

|

If you have any enquiry about quotation or cooperation,please feel free to email us at sunny@chinajsy.com or use the following enquiry form. Our sales will contact you within 24 hours. Thank you for your interest in our products.

GET A QUOTE