-

Since 1996Professional Cardboard Grooving

Since 1996Professional Cardboard Grooving

Machine Manufacturer - Home

- About

- Product

- Service

- Innovations

- Case

- News

- Contact us

-

- EN

Advantages

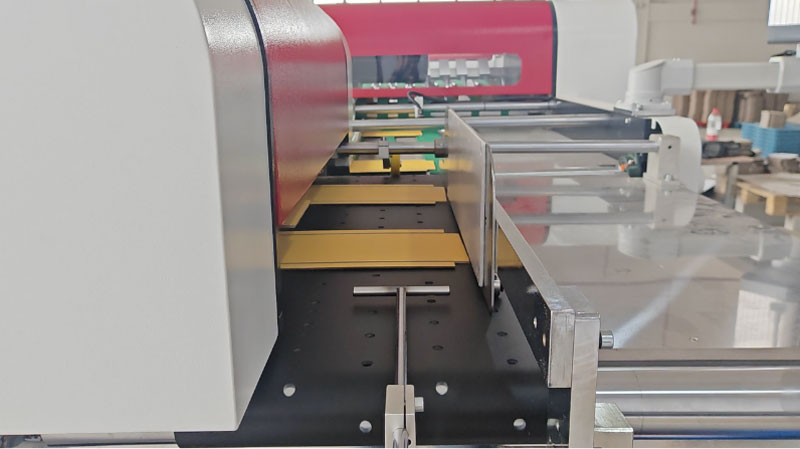

1. The machine is mainly include 3 parts : first grooving part ,second grooving part ,dedicated conveyor belt for delivery final cardboard .

2. Feeding method: The first feeding is the cardboard from top to bottom, after the 1st grooving, the cardboard will be flipped (cardboard turning).Through the vacuum conveyor belt, the cardboard will be steadily transported to the 2nd edge guiding system to ensure that the cardboard enters the 2nd grooving part straightly to ensure the precision of grooving, more importantly, it avoids the problem of blocking the cardboard and the problem of unclean discharging of the wastes.

3. More stable edge guiding system:Use lengthened edge aligning system to ensure that the cardboard go straight into each grooving parts,then improve the grooving accuracy ,to avoid the high and low corners of box by poor grooving accuracy . It does not require high flatness of cardboard, no matter big or small, thick or thin, the cardboard can be smoothly fed into the grooving and ensure high precision.

4. Advantage of durability: brand electrical appliances, beam and knife seat are cast iron, other key positions are cast iron parts, durable and does not affect the accuracy of grooving.

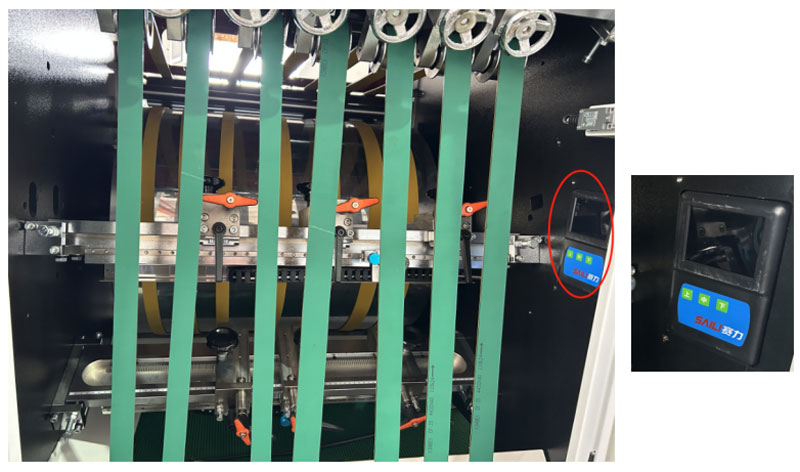

5. The grooving knife is equipped with digital display auxiliary positioning system, which makes it more convenient to adjust the machine.

Improve product quality, improve production efficiency, saves labor .

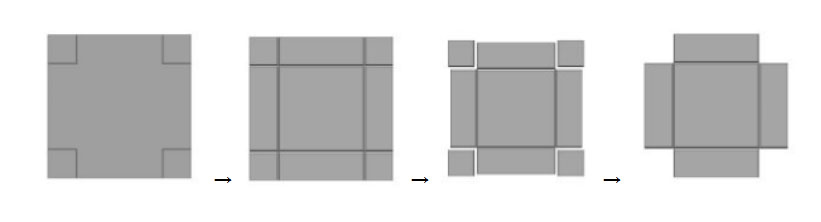

Origin→ crosswise and lengthwise grooving→ after grooving, 4 corners dorp off automatically

A vacuum conveyor ensures that the cardboard is transported straight to the 2nd grooving machine.

Grooving knives: adopt digital display positioning system

3 dedicated conveyor belt for delivery the waste out of the machine automatically

|

Material Width |

150-600mm |

|

Material Length |

150-600mm |

|

Material thickness |

1-5.0mm |

|

The grooving accuracy |

±0.1mm |

|

Grooving angle |

80-140degree adjustable |

|

Grooving tool on the first step |

8sets |

|

Grooving tool on the second step |

4sets |

|

Big Drum number |

2 (diameter 60cm) |

|

Machine power |

5.2KW |

|

Speed |

80-120PCS/Min (200*200mm) |

|

Main dimension |

3462*2533*1525mm |

|

Weight |

2250KGS |

|

Groove shape |

V shape (L shape , U shape customized) |

|

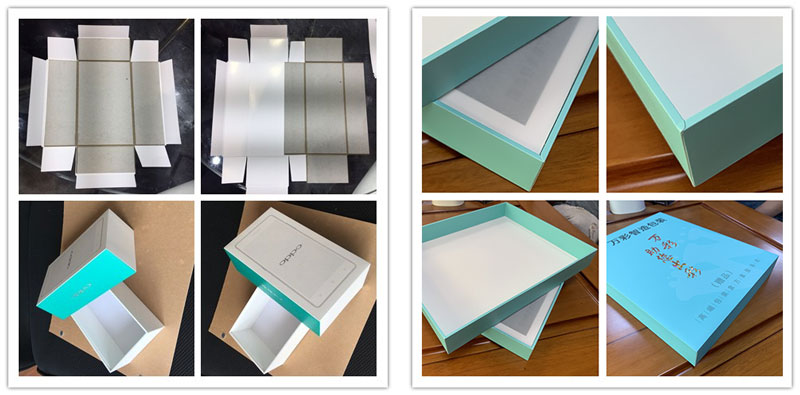

Function : 1 Auto feeding →crosswise grooving →conveying →lengthwise grooving→Auto collector |

|

V groove + L groove

If you have any enquiry about quotation or cooperation,please feel free to email us at sunny@chinajsy.com or use the following enquiry form. Our sales will contact you within 24 hours. Thank you for your interest in our products.

GET A QUOTE