-

Since 1996Professional Cardboard Grooving

Since 1996Professional Cardboard Grooving

Machine Manufacturer - Home

- About

- Product

- Service

- Innovations

- Case

- News

- Contact us

-

- EN

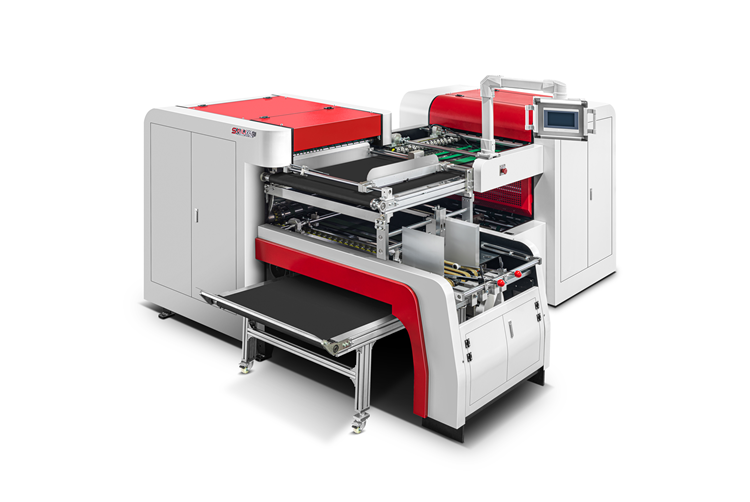

V-grooving machine is a piece of equipment used for cardboard processing. It is mainly used to V-groove cardboard to facilitate folding and assembly. According to its different structural forms, V-shaped grooving machines can be divided into two types: vertical and horizontal.

Vertical V-shaped grooving machine means that the overall structure of the equipment is in a vertical layout, the work surface is perpendicular to the ground, and the operator stands to operate. Vertical V-grooving machines are usually small in size and occupy a small area, making them suitable for use in workplaces with limited space. The vertical V-shaped grooving machine is simple to operate and easy to maintain, and is suitable for use by small carton manufacturers.

Horizontal V-shaped grooving machine means that the overall structure of the equipment is in a horizontal layout, the work surface is placed horizontally on the ground, and the operator sits next to the equipment to operate. Horizontal V-shaped grooving machines are usually suitable for large carton manufacturers. They have high production efficiency, easy operation, and are suitable for long-term continuous operations.

Whether it is a vertical or horizontal V-grooving machine, its main function is to V-groove cardboard to facilitate subsequent folding and assembly. Users can choose the appropriate V-shaped grooving machine model according to their own production needs and site conditions.

How to choose the right cardboard processing equipment

Choosing the right cardboard processing equipment is crucial for ensuring efficient and high-quality production in industries such as packaging, printing, and paper manufacturing. Here are some key factors to consider when selecting cardboard processing equipment:

Production Volume:

Consider the volume of cardboard materials that need to be processed on a daily or weekly basis. Choose equipment that can handle the expected production capacity to avoid bottlenecks and delays in production.

Type of Cardboard Material:

Different types of cardboard materials require specific processing equipment. Consider the thickness, size, and quality of the cardboard material to ensure that the equipment can effectively process the materials without causing damage or defects.

Processing Needs:

Identify the specific processing requirements, such as cutting, creasing, scoring, folding, or printing. Choose equipment that offers the necessary features and capabilities to meet the desired processing needs.

Automation Level:

Determine the level of automation required for the processing equipment. Automated machines can improve efficiency, reduce labor costs, and increase production speed. Consider the complexity of the processing tasks and choose equipment with appropriate automation features.

Space and Layout:

Consider the available space in the production facility and the layout of the processing area. Choose equipment that fits within the space constraints and allows for efficient workflow and material handling.

Maintenance and Support:

Evaluate the maintenance requirements of the equipment and the availability of technical support and spare parts. Choose equipment from reputable manufacturers with a track record of providing reliable maintenance services and support.

Budget:

Consider the budget constraints and cost-effectiveness of the equipment. Compare the prices of different models and brands, taking into account the long-term benefits and return on investment of the equipment.

Technology and Innovation:

Look for equipment that incorporates the latest technology and innovation in cardboard processing. Advanced features such as digital controls, precision cutting mechanisms, and energy-efficient operation can enhance productivity and quality.

By considering these factors and conducting thorough research on the available options, you can choose the right cardboard processing equipment that meets your production needs, quality standards, and budget requirements. It is also recommended to consult with industry experts and equipment suppliers to get expert advice and recommendations based on your specific requirements.

GET A QUOTE