-

Since 1996Professional Cardboard Grooving

Since 1996Professional Cardboard Grooving

Machine Manufacturer - Home

- About

- Product

- Service

- Innovations

- Case

- News

- Contact us

-

- EN

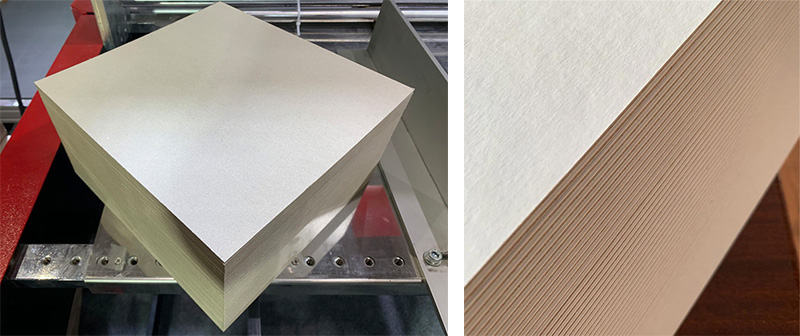

A cardboard slitter is a specialised machine designed to cut large cardboard rolls or cardboard sheets into narrower strips or smaller sizes. This type of machine has a wide range of applications in the packaging industry, with the main aim of improving the efficiency of material preparation and meeting the needs of different product packaging.

Versatile cutting needs: cardboard slitting machines are capable of cutting large cardboard into different widths according to different business needs, thus adapting to various packaging and transport requirements.

High precision and easy operation: these machines are usually characterised by high precision and ease of operation, enabling users to carry out cutting operations with ease while maintaining productivity.

The working principle of a cardboard slitter includes the following steps:

Placing and fixing the material: firstly, the large format cardboard is placed on the machine and fixed with rollers or pneumatic systems.

Cutting area: once the machine is started, the cardboard is fed into the cutting area. In this area, a series of sharp cutting blades move perpendicular to the cardboard. These blades quickly cut the cardboard, dividing it into the required widths.

Rewinding: Once the cutting is complete, the cut cardboard is rewound into small rolls for further processing or direct use in packaging.

The components of a automatic slitting machine include the following:

Cardboard slitting machines are widely used in the following areas:

Packaging industry: used to produce various packaging materials, such as cartons, paper bags, etc.

Printing industry: used to produce printing materials, such as brochures, business cards, etc.

Paper industry: for cutting wide paper rolls into narrower widths for further processing

Modern cardboard slitting machines are usually equipped with automation control systems, such as PID control and fuzzy control technology, which enable precise speed control and efficient production processes. In addition, fully automated cardboard slitting machines can achieve whole pallet loading, automatic board feeding, automatic longitudinal and transversal slitting, automatic waste removal and automatic stacking, resulting in significant savings in labour costs and increased production efficiency.

Cardboard slitting machine is a kind of high-efficiency and automated mechanical equipment, which is widely used in packaging, printing and paper-making industries. Its main function is to slit large sheets of cardboard or paper rolls to specific sizes to meet the needs of subsequent production. Through automated control system and efficient design, cardboard slitting machine can significantly improve production efficiency and product quality.

Booth No: W1-009

Time: May 15-19,2025

Add: China international Exhibition Center (shunyi Hall), Beijing

GET A QUOTE